IRVINE, CA – December 14, 2018 – Dinsmore Inc. significantly expands its capabilities for 3D Printing and Additive Manufacturing services with the Stratasys J750, the only 3D printer to produce full color, multi-material prototypes and parts. A true industry milestone, the J750 breaks restrictive technology barriers, enabling customers for the first time to mix-and-match full color gradients alongside an unprecedented range of materials to achieve one-stop realism.

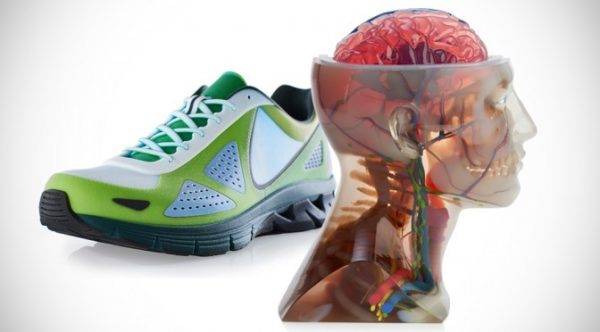

The Stratasys J750 can produce parts in over 500,000 colors, textures, gradients, transparencies and durometers. Offering highly accurate color matching together with an amazing array of textures, this innovation in PolyJet technology creates prototypes that deliver the look, feel, and function of the products they are designed to be. This eliminates costly requirements for painting, assembly, or post-processing, and helps to shrink the prototype cycle by producing parts that are both reliable and consistent, print-after-print. Designers and engineers can physically experience true product prototypes within hours of developing an initial concept for immediate design and function validation. Design decisions can be made instantaneously and with full confidence to help accelerate product delivery.

Key features of the Stratasys J750 include:

- Vivid Color: materials combine excellent detail visualization with strength, a key component in realistic prototypes.

- Automatic color mapping from your design software lets you create photo-realistic models — from neutrals to neons, shadows to highlights and beyond.

- Multiple material selections means the ability to load up to six materials at once, including any combination of rigid, flexible, transparent or opaque materials and their components.

- Double the number of print nozzles in print heads to produce ultra-smooth surfaces and fine details with layer thickness as fine as 0.014 mm—about half the width of a human skin cell.

Streamlining 3D Printing workflows enables the product design and production timelines to become more efficient. Material selection, perfecting the iterations of the buildout process, and the production of the finished part require industry specific expertise, and having an experienced contract manufacturer that can ensure this process would provide an advantage in manufacturing. Dinsmore Inc. has over 20 years experience in the 3D Printing and Additive Manufacturing industries. With the goal of ensuring they are experts in new technology and applications, Dinsmore constantly strives to anticipate solutions for their customers by offering services for such as Design for Prototyping, Design for Additive Manufacturing, 3D Printing, and Rapid Manufacturing as well as a full arsenal of technologies with a wide variety of build platforms.

Learn More

The Dinsmore team will be exhibiting at MD&M West 2019 in Anaheim, CA from February 5-7. Visit Booth #1361 to learn about the services offered using innovations in 3D Printing and Additive Manufacturing technologies to improve your products and processes. Register for MD&M West here.

About Dinsmore Inc.

Founded in 2002, Dinsmore Inc. is a single source provider of 3D Printing, Additive Manufacturing, Design for Prototyping, Rapid Prototyping and Injection Molding services. Dinsmore has more than twenty years of experience with 3D Printing and Additive Manufacturing technology, and is committed to supporting customers throughout the product design and production journey.