Dinsmore Inc. Expands 3D Printing Services with PolyJet J750 System for Prototyping in Full Color and Multiple Materials

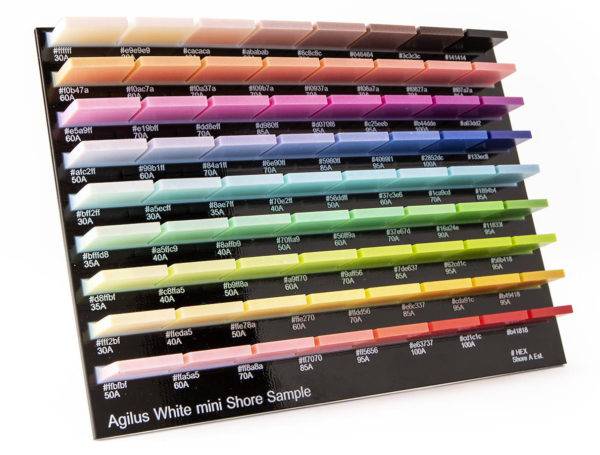

3D Printing can be a complicated process. With new technologies being introduced into the market on both the consumer and industrial end, along with an alphabet of 3D printing materials to select from, can make even getting started a daunting task to undertake. Companies that offer 3D printing services need to be experts in both the technologies and materials offered. If you’re looking to start on a project that requires a realistic prototype, PolyJet technology offers a multifaceted solution. Dinsmore Inc. in Irvine, CA recently added the J750, a PolyJet printer to its expanding Additive Manufacturing technology arsenal. The J750 is capable of producing parts from a selection of over 360,000 colors, textures, gradients, transparencies, and durometers. It can create prototypes that look and feel like finished products, requiring no added assembly or painting.

Premium Adaptability

A machine with this much versatility requires a service provider that understands the materials and how each customer’s specific finished product needs to look. Able to print several different types of materials—from opaque to transparent, flexible to rigid—all types can be applied to a single job if required. This means that applications that previously required multiple systems, now can be completed in one single build using the J750.

Improve Your Design Workflow

PolyJet provides prototypes, models, and patterns in high resolution and detail so that you can have the freedom to design in vivid color and be able to get a feel of the final product. From flexibility to opacity, the J750 accommodates multiple material combinations to produce realistic models with the ability to apply texture patterns like wood grain and printed photos. High end concept models can be developed without any tooling, and are ready to present in the boardroom straight off the machine.

Design Partners

Designing products that will be produced using PolyJet technology may be an iterative process, depending on your design expectations. Working with a service bureau that understands the technology and how it can be used for each individual customer’s project is key to success when using PolyJet to produce prototypes. Dinsmore Inc. has over 20 years of experience across multiple additive manufacturing technologies, giving customers the assurance of knowing they will be matched with the best fit solution for their application. Fast turnarounds and expertise in using 3D printing technology to provide solutions to customers across the Medical, Automotive, Aerospace, Consumer, and Educational industries, Dinsmore Inc. understands the need for speed and precision when meeting your project’s demands. Contact Dinsmore Inc. today to request a quote for your project.