Dinsmore Inc. Welcomes A Little Dynasty Chinese School for a Day of 3D Printing

Dinsmore Inc., a premier 3D printing and additive manufacturing service bureau located in Irvine, CA, had the pleasure of hosting 80 young students from A Little Dynasty (ALD) Chinese School for a day of discovery. ALD specializes in immersing students of all backgrounds in hands-on environments that help to nurture their sense curiosity while learning to improve their Chinese language skills. During the interactive tour, students were introduced to a variety of 3D printed parts, diverse processes, and innovative technologies.

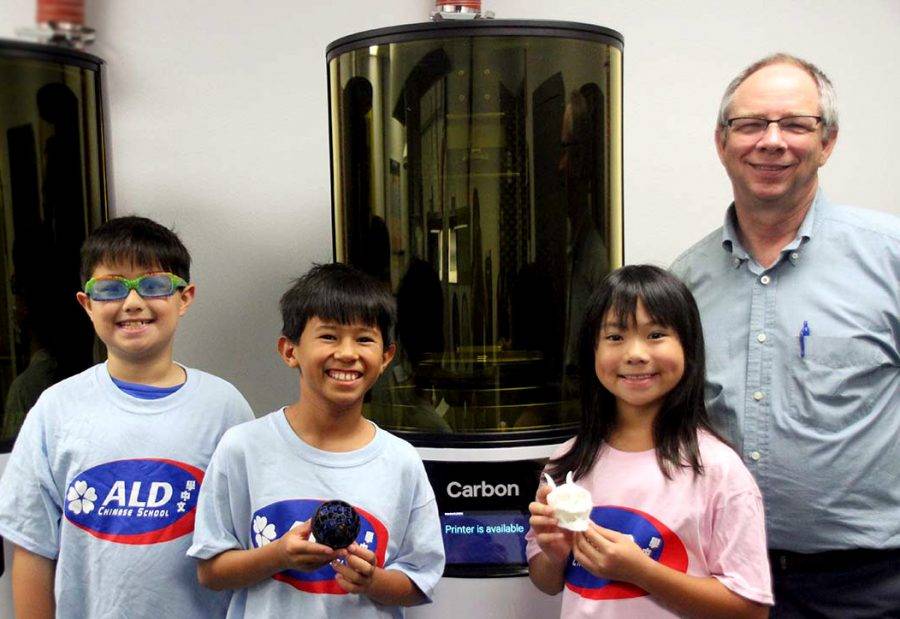

One of the featured technologies included in the tour was Carbon’s Digital Light Synthesis (DLS) which “uses digital light projection, oxygen permeable optics, and programmable liquid resins to produce parts with excellent mechanical properties, resolution, and surface finish.” Students were able to learn about this technology first-hand in Dinsmore’s newly designed Carbon Lab which exclusively produces parts via this cutting-edge process. Students shared their ambitions for using this technology for everything from printing houses for the homeless to designing new inventions.

In the main lab, students were able to see how 3D printing can combine several materials and colors into a single intricate model using Stratasys’ PolyJet Technology. PolyJet builds parts using “multiple print heads to deposit liquid plastic onto a clean build platform, layer by layer.” With this technology, complex geometries can be produced with “microscopic layer resolution and accuracies down to .01mm,” and in materials that can simulate anything from clear, flexible, and rigid. Students were able to hold finished parts from medical models to sunglasses, displaying the spectrum of how creative one can get with 3D printing using this technology.

Another technology featured on the tour was Stereolithography (SLA) on a large-scale via 3D System’s PROX 800 which uses a “very wide spectrum of Accura® additive manufacturing materials.” SLA enables the production of parts with “polypropylene-like, tough/durable, clear, casting, high temp composites and specialty materials.” The PROX 800 system is capable of building massive parts as large as 650mm x 750mm x 550mm with high accuracy.

At the end of the tour, each student received a souvenir from their day at Dinsmore—a dog to celebrate the year of 2018 which is the Chinese zodiac of the dog. Dinsmore Inc. is passionate about the 3D Printing and Additive Manufacturing industries and encourages educational visits. If you’d like to schedule an educational tour or if you’re curious about how you can improve current prototyping process using the latest technologies, please feel free to contact us or reach us directly at (888) 496-3406.