Technology:

FDM

Applications:

Ducts, electrical housings, electrical connectors, composite layup tooling, medical devices, production tooling, food packaging.

Description:

FDM Technology uses the same tried and tested thermoplastics found in traditional manufacturing processes. ULTEM 1010 resin offers the highest heat resistance, chemical resistance and tensile strength of any FDM thermoplastic.

Features:

Flame-retardant. Chemical resistant. High heat resistance. Lowest coefficient of thermal expansion (CTE) of any FDM® thermoplastic. Certified grade-food contact and biocompatibility compliance.

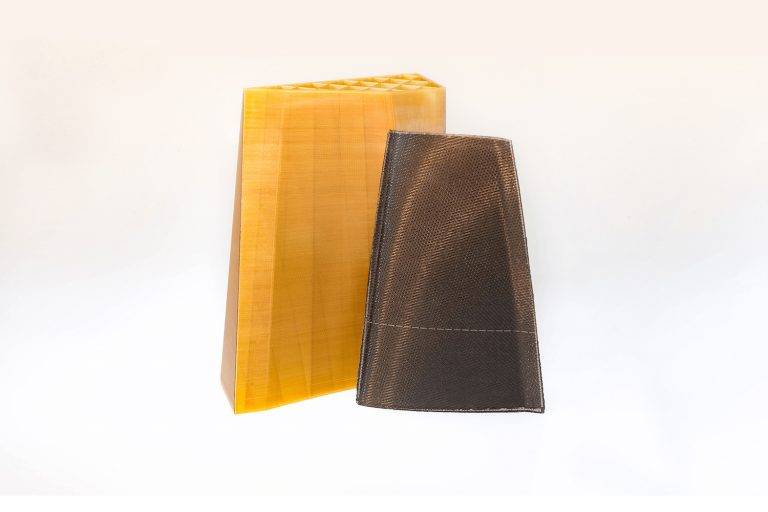

Color Options: Amber

| Property | ASTM | Metric Units |

|---|---|---|

| Tensile Strength | D638M | 42 MPa |

| Modulus of Elasticity, Youngs Modulus | D638M | 2,200 MPa |

| Elongation at Break (%) | D638M | 2% |

| Flexural Strength | D670M | 72 MPa |

| Flexural Modulus | D670M | 2,230 MPa |

| IZOD Impact (notched) | D256A | 24 J/m |

| Heat Deflection Temperature @ 0.45 MPa/66 psi, (°C) | D648 | 216°C |